Vinyl crafting is a popular hobby, and knowing how to properly put vinyl on a cutting mat is crucial for successful projects. This guide will walk you through the steps to ensure your vinyl adheres perfectly to your cutting mat, making your cuts precise and clean.

Gather Your Materials

Before you start, make sure you have all the necessary materials:

- Vinyl sheet or roll

- Cutting mat

- Scraper tool or credit card

- Scissors or rotary cutter

- Cleaning supplies (if needed)

Clean the Cutting Mat

Ensure your cutting mat is clean and free from dust and debris to maintain its efficiency. Start by using a lint roller to remove loose particles. For deeper cleaning, use a slightly damp cloth to wipe the surface gently. Regular cleaning enhances adhesion, ensuring your materials stay in place during cutting, and promotes more accurate cuts. A well-maintained cutting mat not only extends its lifespan but also improves the quality of your projects. Keep your workspace tidy and your tools in top condition for the best crafting results. Clean your cutting mat regularly for optimal performance and precision.

Measure and Cut the Vinyl

Measuring and cutting vinyl accurately is essential for any project. Start by determining the size of the piece required. Use a ruler or tape measure to ensure precise measurements. Once you have the dimensions, use sharp scissors or a rotary cutter to cut the vinyl. Be careful to cut along straight lines to avoid any jagged edges. Place the vinyl on a cutting mat to prevent damage to your work surface and to keep the steady. Ensuring the piece fits well within the cutting mat’s dimensions will help you achieve a clean and professional cut every time.

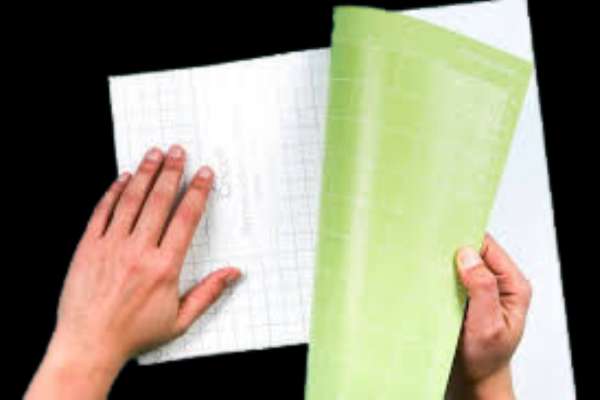

Peel the Vinyl Backing

Carefully peel the backing off the vinyl. Begin at one corner and slowly work your way across, ensuring the vinyl stays smooth. Take your time to prevent curling or wrinkling, which can compromise the final look. Maintaining a steady pace and a gentle touch will help achieve a flawless application. This step is crucial for ensuring the adheres properly and looks professional. Properly peeling the backing not only enhances the appearance but also increases the durability and lifespan of the vinyl. Following these steps can significantly improve the overall quality of your vinyl projects.

Position the Vinyl on the Mat

How to put vinyl on cutting mat- Align the top edge of the vinyl with the top of the cutting mat for a precise cut. Carefully lay the vinyl down, ensuring it’s smooth and free of bubbles or wrinkles. Use your hands to gently press and smooth the vinyl as you go, maintaining even pressure. This careful placement ensures that your cuts are clean and accurate, resulting in professional-quality projects. Properly positioning the vinyl on the mat is crucial for achieving the best results in your crafting or DIY projects. This method enhances the precision and quality of your work, boosting both your satisfaction and your project’s success.

Smooth the vinyl

To achieve a perfectly smooth surface, use a scraper tool or a credit card. Begin in the center of the vinyl and work your way outward. Apply even pressure to remove air bubbles and ensure the vinyl adheres uniformly to the mat. This technique not only enhances the appearance but also improves the durability of your project. Consistently smoothing the vinyl prevents wrinkles and creases, making your finished product look professional. Remember to work slowly and carefully for the best results. This method is effective for all types of vinyl applications, ensuring a flawless finish every time.

Check for Bubbles and Wrinkles

When applying vinyl, it’s crucial to check for bubbles and wrinkles to ensure a smooth finish. Inspect the surface carefully for any imperfections. If you spot bubbles or wrinkles, gently lift the vinyl and reposition it. Use a scraper tool to smooth it out again, applying firm pressure to remove any trapped air. This process helps maintain a flawless appearance and ensures the adheres properly. Regularly checking and correcting these issues can improve the overall look and longevity of your vinyl application, making it more appealing and durable.

Secure the vinyl

Ensure your vinyl is securely attached to the mat, particularly along the edges. Proper adhesion is crucial to prevent the vinyl from shifting during cutting. Use a strong adhesive or ensure your mat is tacky enough to hold them in place. This step is vital for precise cuts and professional-looking results. Double-check the position before starting the cut to avoid errors. A well-secured also extends the life of your cutting mat by reducing unnecessary wear and tear. For the best outcomes, always prioritize securing the properly before cutting.

Load the Mat into the Cutting Machine

Carefully load the cutting mat with the vinyl into your cutting machine. Ensure it is properly aligned and securely in place according to the machine’s guidelines. Accurate alignment prevents material waste and ensures precise cuts. Double-check that the vinyl is firmly attached to the mat to avoid slipping during the cutting process. Adjust the machine settings based on the vinyl type for optimal results. Following these steps ensures smooth operation and high-quality cuts, enhancing your crafting projects’ overall appearance. Proper loading of the cutting mat contributes significantly to successful cutting outcomes and maximizes your machine’s efficiency.

Select the Correct Cut Settings

When working with vinyl, setting your cutting machine to the correct settings is crucial for achieving clean and precise cuts. Start by adjusting the blade depth to match the thickness of your vinyl. Next, modify the pressure settings to ensure the blade cuts through without tearing. Finally, set the speed according to the type of vinyl slower speeds often yield better results with thicker materials. Testing on a small piece of before your main project can help fine-tune these settings, ensuring a smooth and efficient cutting process. Correct settings not only extend the life of your blade but also guarantee professional-looking results.

Perform a Test Cut

Performing a test cut on a small section of vinyl is essential to ensure your settings are accurate. This crucial step helps you avoid costly mistakes and ensures a clean, precise cut. Begin by selecting a small, inconspicuous area of the vinyl. Set your cutting machine to the desired settings and execute the test cut. Examine the results closely, checking for any issues with alignment or depth. Adjust your settings if necessary and repeat the test until you achieve the perfect cut. This practice not only saves material but also guarantees a flawless finish for your final project.

Start the Cutting Process

Begin the cutting process once you are satisfied with the test cut. Ensure that your cutting machine is properly set up and ready to go. As the machine starts, monitor it closely to make sure everything runs smoothly. Pay attention to the blade alignment and cutting speed, making adjustments if necessary. Keep an eye on the material being cut to avoid any mistakes or mishaps. By staying vigilant and attentive, you can ensure a precise and efficient cutting process, resulting in high-quality outcomes and minimizing waste. This careful oversight helps in achieving the best results and maintaining machine efficiency.

Remove the Vinyl from the Mat

Removing vinyl from the mat after cutting is a delicate process that requires care to avoid damaging your design. Start by gently peeling the vinyl away from the mat, ensuring you do so slowly and steadily. To assist, use a scraper tool to lift the edges of the without tearing it. This tool helps maintain the integrity of your cut design while making the removal process smoother. Properly removing them ensures your projects remain pristine and ready for use. By following these steps, you can efficiently and safely handle your vinyl, keeping your designs intact and beautiful.

Clean the Mat After Use

After using your cutting mat, cleaning it properly ensures its longevity and optimal performance. Start by gently removing any leftover vinyl or debris. Use a soft brush or cloth to wipe the surface clean. For a deeper clean, use a mild soap solution and rinse thoroughly with water, ensuring no soap residue remains. Dry the mat completely before storing it flat to prevent warping. Regular maintenance not only keeps your mat in top condition but also enhances the quality of your future projects. Keep your cutting mat clean and ready for use to maximize its lifespan and maintain precision in your work.

Store Your Vinyl Properly

Properly storing your vinyl is essential for maintaining its quality and longevity. Always keep your leftover vinyl in a cool, dry place, away from direct sunlight and moisture. Roll it up neatly or lay it flat to avoid wrinkles and damage. Ensure it’s stored in a dust-free environment to prevent any unwanted particles from sticking. Using storage tubes or original packaging can help preserve its shape. By following these simple steps, you’ll keep in excellent condition, ready for your next creative project. Proper storage not only prolongs the vinyl’s life but also ensures its performance when you need it.

Conclusion

Putting vinyl on a cutting mat correctly is essential for successful crafting projects. By following these steps, you can ensure your vinyl adheres properly, leading to precise and clean cuts. Happy crafting!

This article provides a detailed, step-by-step guide to help users properly place vinyl on a cutting mat, ensuring a successful crafting experience. Following these tips will improve your results and make your crafting process smoother and more enjoyable.